If we were to ask you exactly how many units of your fourth best-selling product you’ll have in each warehouse location today and how long that inventory will last, would you be able to answer with confidence?

If you don’t have the right inventory optimization software, your answer may be “no,” and we don’t mean to be alarming… but if that’s the case, that answer should scare you.

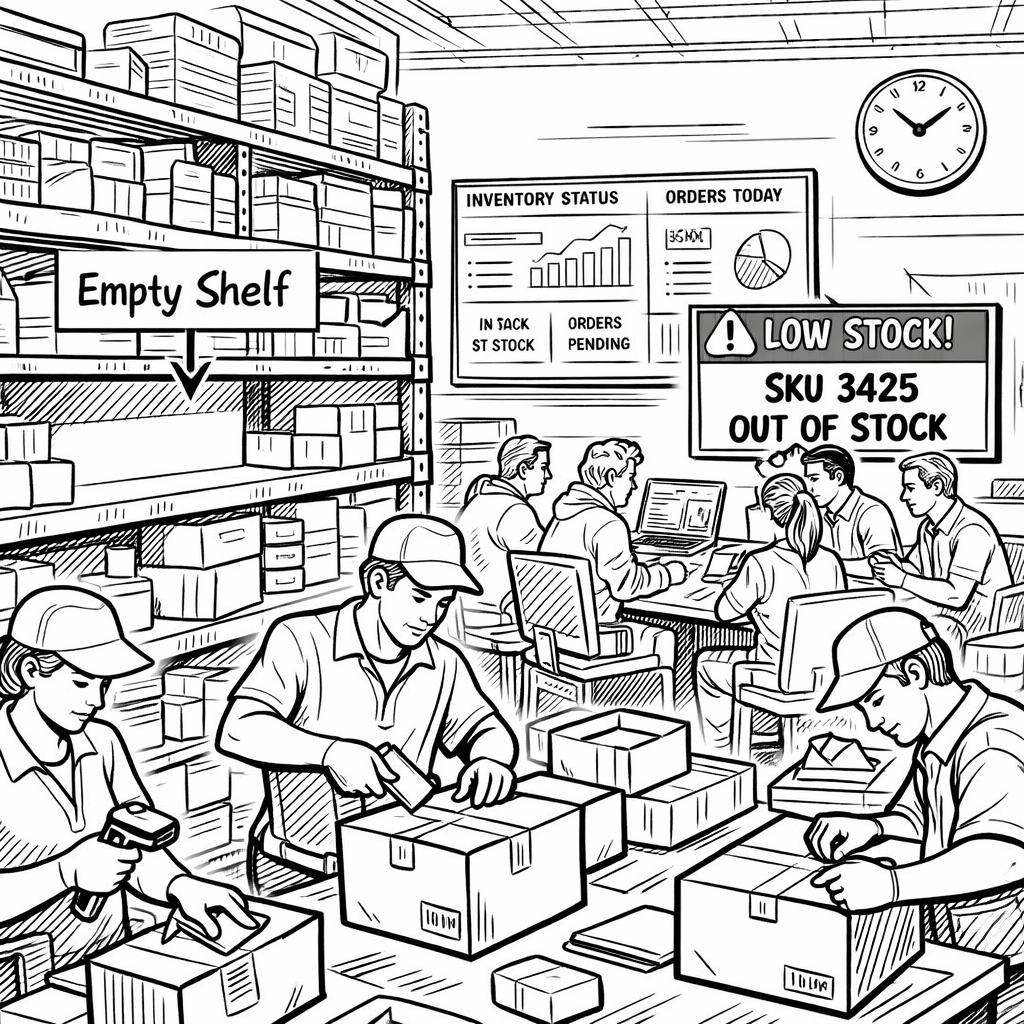

Effective inventory planning is a challenging—and essential—endeavor for any retailer. Changing demand, limited visibility, and complex supply chains contribute to the already difficult task of managing inventory across multiple warehouses to fulfill multiple sales channels. To optimize your inventory, you need to consolidate data from multiple sources and coordinate various players in the supply chain. You need help predicting demand and ensuring that you have the right products in the right quantities at the right location every time.

The simple solution to these challenges is implementing efficient inventory optimization software, which brings us to the question: How do I know which inventory optimization software is right for my business? This post will provide you with the best—and worst—solutions for inventory optimization software. We’ll discuss features, benefits, and reviews.

Choosing the Best Inventory Optimization Software

Before we provide our list of top solutions for inventory optimization software in the current climate, let’s first establish what inventory optimization software is. Inventory optimization software is a technical solution that helps you better identify which inventory to replenish and calculate when and where your inventory should be replenished and distributed.

Implementing a solid inventory optimization system provides many advantages to your business. These benefits can be divided into two categories: Operational benefits and strategic benefits.

Operational Benefits

Data reliability is the first operational benefit you’ll see from using effective inventory optimization software. Using inventory optimization software makes your data more reliable because you replace fallible, manual processes with much more reliable, automated ones. By reducing human error, you’ll have regular access to inventory data you can rely on.

Next, you’ll also experience the benefit of data visibility. Supply chains can be frustratingly opaque. This opacity is mainly due to the number of players and processes involved and the number of data sources at hand. With inventory optimization software, your data is all in one portal, giving you the full picture of your inventory and making it easier to make the right decisions when it comes to planning.

Inventory optimization also provides the benefit of time reduction. Improved data reliability isn’t the only advantage you’ll see from reducing manual work: You’ll also save time. You and your staff will reduce the time you need to spend managing inventory and your supply chain, enabling you to focus on other efforts that matter to your business.

Lastly, you’ll see improved accuracy regarding forecasting and other inventory planning efforts when you use inventory optimization software. Sophisticated algorithmic models and machine learning will provide you with better estimates to make more informed decisions about your inventory planning processes.

Strategic Benefits

Optimizing your inventory with the right software will also provide strategic benefits like an increase in sales. With the right inventory software, you’ll be able to better align your inventory availability with demand. In other words, you’ll have fewer stockouts.

You’ll also see an increase in margins. Stockouts are only one piece of the puzzle for inventory woes: Inventory optimization software will also help you avoid overstock and deadstock. Your supply chain processes will be more efficient, helping you to pay for only the storage you actually need.

Lastly, you’ll enjoy the benefit of a reduction in capital invested. Since your inventory is leaner, your capital won’t be tied up in inventory that isn’t immediately selling. That means you can allocate that capital elsewhere.

Top Solutions

1. Cogsy

Cogsy positions itself as an “extra Head of Operations” for your business. This software solution is designed to service direct-to-consumer sales and boasts benefits like time savings and increased revenue.

Some of Cogsy’s top features include:

- Proactive Sales Prediction: Cogsy provides automated sales forecasting.

- Selling on Backorder: Even if you stock out, you can sell items on backorder with automated shipping date estimates for customers.

- Tech Stack Integrations: Cogsy integrates with Shopify, Skubana, Anvyl, and more.

Cogsy is a great solution for businesses currently struggling with inefficiencies in their operations that need a quick fix. However, it’s not necessarily a best fit for businesses looking to improve their demand planning efforts.

“Cogsy is the hub and real-time source of truth for our operational data. We're now able to plan for each upcoming quarter with more clarity and accuracy.” -Cogsy Customer

2. Blue Ridge

Blue Ridge is a demand planning solution that promises to help you build a more resilient supply chain. Blue Ridge also offers you customizable configurations, enabling you to build the planning platform that works best for your business.

Some of the features Blue Ridge offers include:

- Robust Analytics: View all your reporting and analytics in a single dashboard.

- Price Optimization: Determine the outcome of a potential price change before you make things official.

- ERP Integration: Blue Ridge promises to integrate with your ERP of choice seamlessly.

Blue Ridge has all the bells and whistles, making it an excellent solution for larger, Fortune 1000 companies. However, it is on the pricier side, which may put it out of reach for smaller, growing businesses.

“Blue Ridge provides in-depth training so that a user knows how to do the proper forecasting and setup so that once that is done buying is very quick. The application is also equipped with tools to quickly filter and pull out items that NEED attention now…” -Blue Ridge Customer

3. SoStocked

SoStocked is an inventory management solution tailored to Amazon sellers. By analyzing specific pain points of Amazon sellers, SoStocked is able to counter those struggles with specific and targeted features.

Some of the features SoStocked offers include:

- Adjustable Velocity: Use daily sales velocity adjusted for sales spikes and stockouts for your estimates instead of using monthly sales totals.

- Buffer Stock: Set up a “false zero” alert to trigger you to order before you stock out.

- KPI Dashboards: View your progress toward your key performance indicators in a single-view dashboard.

SoStocked is an excellent solution for Amazon sellers. However, it does not offer multichannel selling solutions.

“Saves me so much time. Reliable customer support allows my VA to learn without my help.” -SoStocked Customer

4. Flieber

Flieber is a demand planning and inventory optimization solution targeted at direct-to-consumer brands. We focus on ensuring you can reliably have the right products in the right quantities in the right place at the right time.

Flieber’s solution is jam-packed with helpful features including:

- Advanced Demand Planning Features: Accurate inventory forecasting is the bread-and-butter of our software solution. Plan ahead with accurate forecasting calculated with the help of AI and machine learning.

- Timely Replenishment Capabilities: Never stock out again with features that let you know when you need to purchase or transfer orders.

- Real-Time Adjustments: Accommodate delays or unexpected demand on-the-fly by accelerating delivery or managing sales and marketing efforts to help stretch your inventory further.

- The Right Integrations: Seamlessly integrate with Amazon, Shopify, Netsuite, Deliverr, Flexport, Anvyl, Excel, and more.

Flieber’s solution connects real-time data from various sources, giving you all the information you need to make the best decisions regarding your inventory. Our software is the best fit for direct-to-consumer sellers looking to synchronize their sales velocity, supply chain operations, and inventory management processes.

“Flieber enabled us to plan our financials throughout the year in a way that allowed us to not only save money but also have our products available 100% of the time. We had no idea how much money we were losing due to stockouts and Flieber solved that with a cost that is just a fraction of those losses.” -Basics Hardware, Flieber Customer

Worst Solutions

1. Manual Spreadsheets and 10 Browser Tabs

One of the worst ways you can track inventory and perform demand planning is to attempt to calculate things manually using spreadsheets to try to combine data from multiple sources by hand.

Many businesses stick with this solution because of the price. Manual spreadsheets are, on the surface, very inexpensive to implement. However, over time this solution will cost your business far more than you would likely spend on a more efficient solution. You’ll lose money due to:

- Inaccurate Forecasting: Human error is rampant in any manual process. Relying on hand calculations and complicated spreadsheets to forecast your inventory needs will inevitably result in stockouts, costing you revenue.

- Worker Hours: Manual processes take time. You or your staff will burn dozens of hours each month calculating inventory manually.

- Warehousing Costs: Padding inventory to avoid stockouts is a common tactic for businesses without the ability to forecast their needs accurately. This over-bloated inventory will cost more to store than the leaner inventory you would be able to keep on hand with better inventory optimization.

2. Your Best Guesstimations

Similar to manual tracking, some businesses attempt to manage their inventory based on gut feel alone. Though this solution is undeniably cheap on the front end, it will be incredibly expensive on the back end in terms of lost revenue to stockouts, higher costs due to overstock, and lost capital due to dead stock.

Getting the Most From Your Inventory Optimization Software

We’ve seen great and poor options for inventory optimization software, but how do you select the right solution for your business? To get the most from your inventory optimization software, you should follow a simple, five-step process:

- Define your goals

What do you hope to accomplish with your inventory optimization efforts? The answer to this question will guide your software solution decision. - Determine the basics

What do you need your software to accomplish? How large is your business? How many locations do you need to coordinate? Additionally, do you have any current tech solutions that need to integrate with your solution? - Establish key features

Determine the features you need from your inventory optimization software to be successful. Look for solutions with these features included. - Consider reviews and testimonials

The best way to get a sense of how well a solution performs is to see what current customers say about the solution. Read reviews online and examine testimonials and case studies if possible. - See it in action

Even after steps one through four, there is only one true way to see if a software solution is a right fit for your business: See it in action. Ensure you’re exploring a solution that offers a demo or walk-through so you can see the system at work.

Flieber’s solution is designed for brands selling direct-to-consumer. Our system uses advanced data analytics and machine learning to identify future demand and provides the tools for planning and replenishing inventory to align with the demand: Sales and inventory in perfect harmony.

Schedule a free demo today to see Flieber in action and see how we can help you reduce stockout, overstock, and other inventory-related challenges.