Scaled to

$30M in sales

Superpower your inventory decisions

As your brand scales, replenishment decisions get hard—and your spreadsheets become a nightmare. Flieber connects to your sales, inventory, and supply chain data to give you full visibility and precise recommendations. With Flieber, inventory decisions become smarter, faster, and easier.

4.7

Rating on

3M+

SKUs

50,000+

Annual POs/TOs

15+

Countries Served

Why does decision-making get insanely difficult as your brand grows?

Because modern operators like you run into unique inventory challenges that can quickly become a nightmare. These include:

Forecasting omni-channel sales (wholesale,

DTC, and marketplaces all at once)

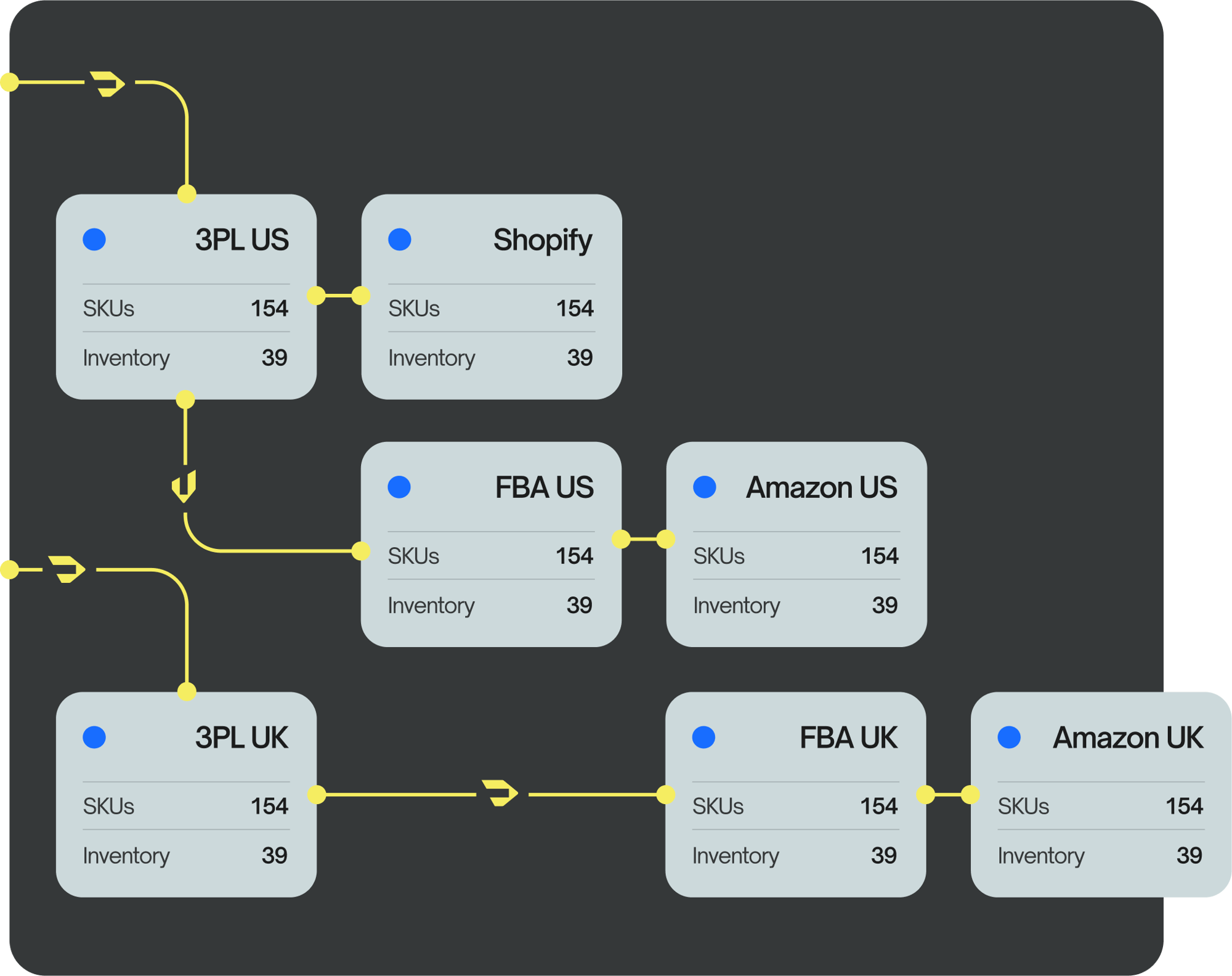

Setting different replenishment paths

for different channels

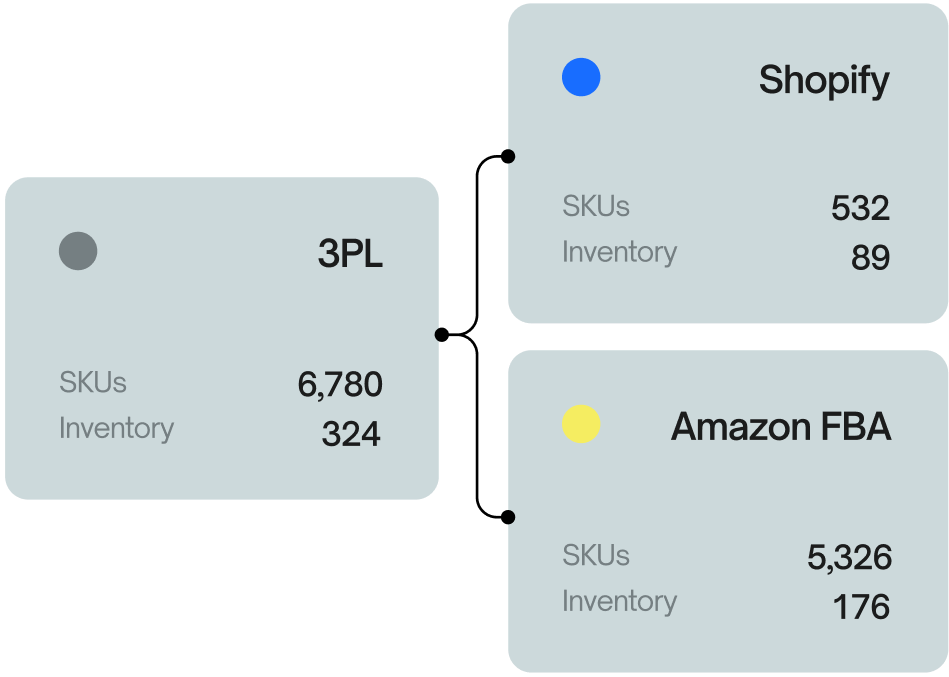

Forecasting inventory for multiple

warehouses, FBA, and 3PL locations

Keeping the right amount

of stock for seasonal fluctuations

Preventing stockouts from

significant sales spikes

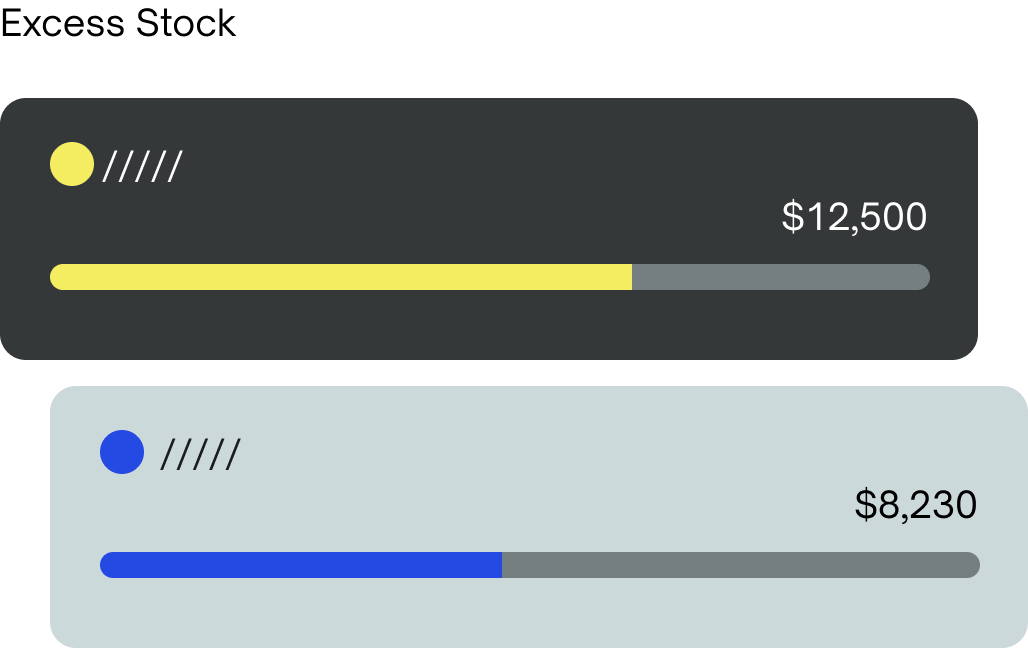

Avoiding trapped capital

in overstocked inventory

Not an IMS or ERP. The inventory planning tool you need to make smart decisions.

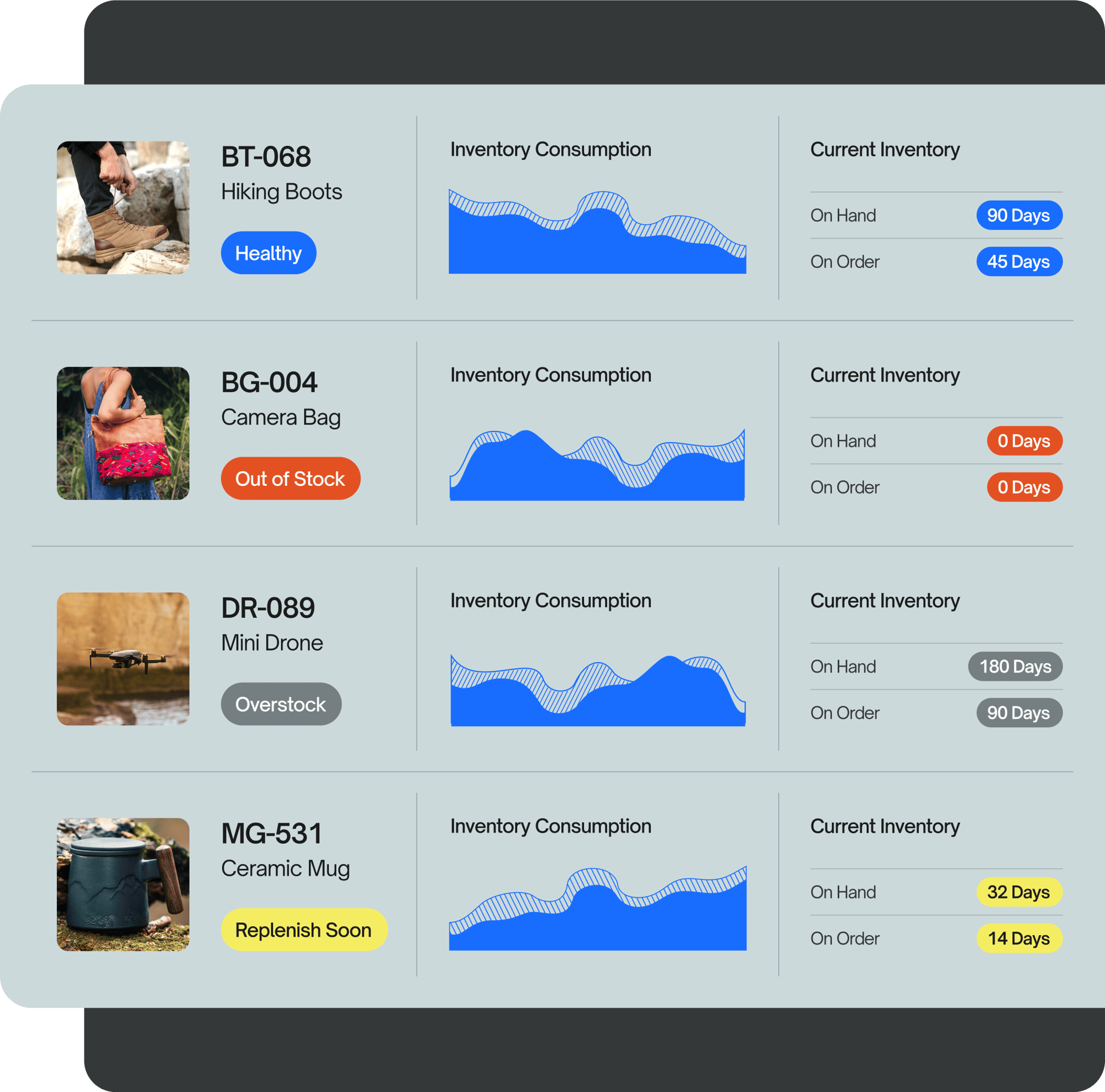

Flieber combines real-time sales, inventory and supply chain data to recommend what you should purchase or transfer to stay at the optimal stock level in all your inventory locations. The typical result is a 62% reduction in stockouts over the first year alone.

Fewer stockouts and overstocks, higher margins and peace of mind

Real results from all customers using Flieber for 1+ year:

increase in sales

reduction in stockouts

reduction in capital trapped in stock

less time spent on forecasting

Inventory decisions in minutes instead of hours

Too many brands end up stuck using forecasting spreadsheets because nothing else works. Flieber is the first tool that can supercharge all your forecasting sheets for every use case and platform.

With Flieber, data automatically comes in, and forecasts automatically go out—so you can make decisions in minutes instead of hours.

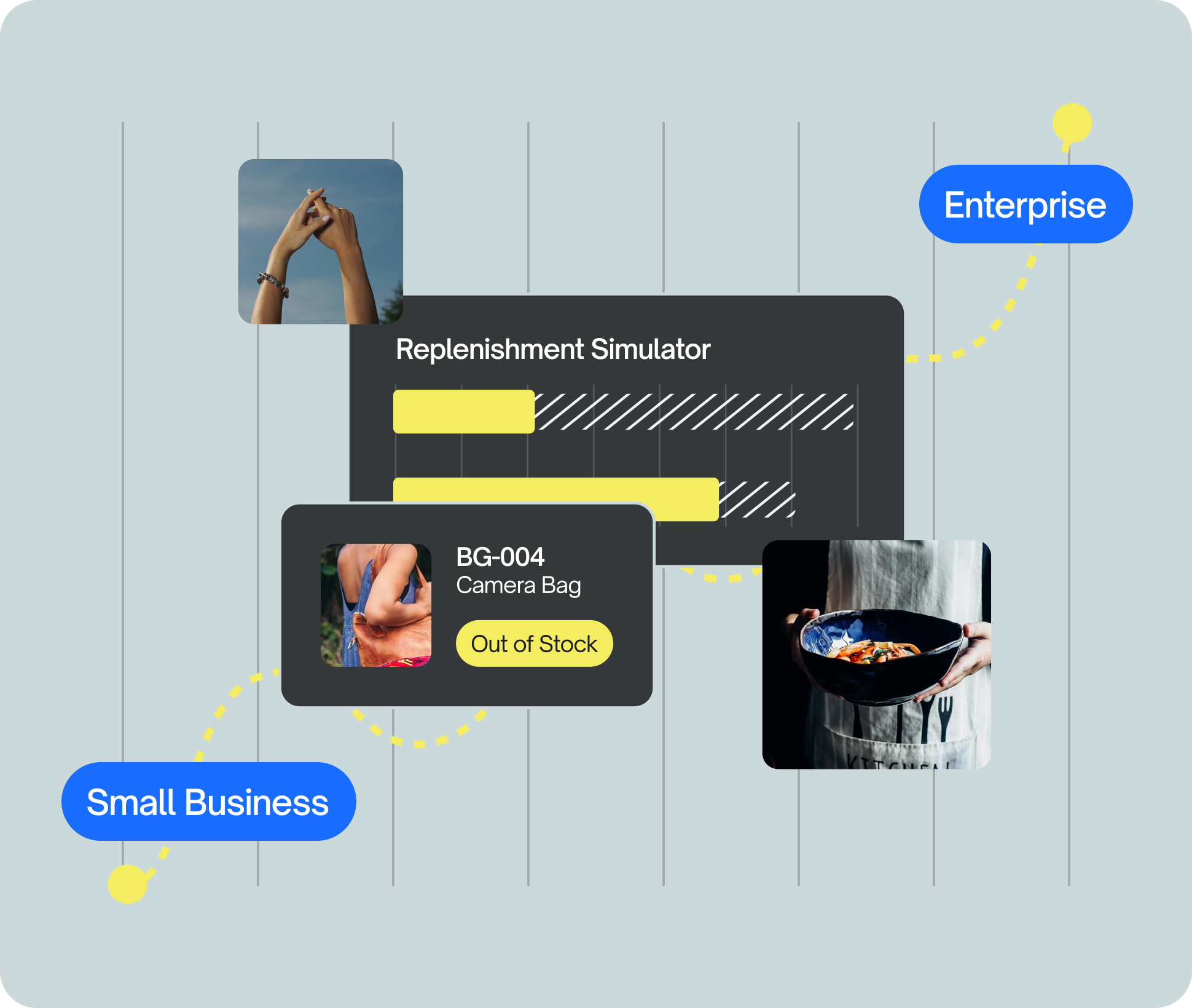

The right decision-making tool for scaling brands

Growing brands end up stuck between spreadsheets, basic tools that don’t get the job done, or expensive enterprise solutions. Flieber is perfectly situated in the middle–a sophisticated tool at a manageable cost.

.png?height=2000&name=Box%20(3).png)

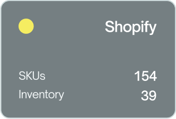

Works whether you have an ERP or not

Don’t have an ERP? No worries, Flieber can become your system of record by integrating with all your 3PLs, sales, and inventory platforms. Have an ERP? Flieber can sit on top of your ERP and augment it with better, faster decision-making capabilities.

Our operators feel the difference

Jenn Angel

COO at Zugu Case

"Flieber is helping us effectively manage stock across all of our sales channels by customizing our calculations to the data points that are important to us, which ultimately allows us to stay lean on stock. It also alerts us to potential stock issues so they can be corrected immediately. The way it simplifies the data into screens that give you a full grasp of the situation within seconds, is invaluable."

Leonardo Escalona

Inventory Planner at Primal Harvest

"Flieber is a powerful and customizable tool. But what I like most about them is their customer support approach: they are genuinely interested in learning how you operate to support you better. Flieber has allowed me to reduce manual work while planning and forecasting products, and to handle different regions and sales channels in a single place."

Sohail Chaudry

CEO at Southshore Fine Linens

"Before signing up with Flieber, it used to take days before we could place a complete order with factories and even then, it felt like our best guess. This has changed now. We are able to see our sales and forecasting across all channels and order what is needed, not locking down cash in slow-moving inventory."

Bryan Smallwood

Supply Chain Manager at Unybrands

"Flieber creates a 'one stop shop' where I can see demand level data across all my brands and make educated replenishment decisions based on inventory positions. Its forecasting engine also populates our inventory positions giving us a single source for supply chain planning."

Stephanie Buchholtz

VP of Merchandise Planning at Modloft

"We have always been challenged with out of stock inventory and long leadtimes. Flieber was a game changer for us. The interface is easy to use, with a bunch of critical information, and their algorithms that provide recommendations are top notch."

Tehsin Rashad

Operations Manager at Lifepro Fitness

"Finally a software that considers everything. Flieber considers all variables that no other software is able to pick up. It has helped us eliminate unnecessary stockouts that would hurt our Amazon business."

Wesley Wey

VP of Operations at Cabinet Health

"Flieber allows us to leverage technology to make demand planning and forecasting more streamlined and efficient. As a result, we have a less error prone process and have more time to spend making strategic decisions vs. data clean-up/analysis."

Hamza Khan

Project Manager at Wargames Delivered

"Flieber's people are simply amazing. They are making inventory management and forecasting more accurate and easier, allowing us to make data-based decisions quicker."

James Kelly

Co-Founder at Jagerita Holdings

"Flieber has replaced an extremely time intensive piece of our work with better results. It helps me predict my mid to long term demand and inventory replenishment needs. This is immensely important due to my long lead times and complex product portfolio due to multi-channel variation. It's great to have a tool that automates so much of this process."

Sara Maya

Supply Chain Manager at We The Brands

"Flieber efficiently consolidates data through integrations, simplifying decision-making and saving significant time. Its user-friendly interface ensures easy navigation, making it a valuable tool for streamlining operations and boosting productivity. Flieber is a game-change for supply chain planning in e-commerce companies."

Slashed

stockouts

by 120%

Scaled to

$30M in sales

Slashed

stockouts

by 120%

Jenn Angel

COO at Zugu Case

"Flieber is helping us effectively manage stock across all of our sales channels by customizing our calculations to the data points that are important to us, which ultimately allows us to stay lean on stock. It also alerts us to potential stock issues so they can be corrected immediately. The way it simplifies the data into screens that give you a full grasp of the situation within seconds, is invaluable."

Leonardo Escalona

Inventory Planner at Primal Harvest

"Flieber is a powerful and customizable tool. But what I like most about them is their customer support approach: they are genuinely interested in learning how you operate to support you better. Flieber has allowed me to reduce manual work while planning and forecasting products, and to handle different regions and sales channels in a single place."

Sohail Chaudry

CEO at Southshore Fine Linens

"Before signing up with Flieber, it used to take days before we could place a complete order with factories and even then, it felt like our best guess. This has changed now. We are able to see our sales and forecasting across all channels and order what is needed, not locking down cash in slow-moving inventory."

Bryan Smallwood

Supply Chain Manager at Unybrands

"Flieber creates a 'one stop shop' where I can see demand level data across all my brands and make educated replenishment decisions based on inventory positions. Its forecasting engine also populates our inventory positions giving us a single source for supply chain planning."

Stephanie Buchholtz

VP of Merchandise Planning at Modloft

"We have always been challenged with out of stock inventory and long leadtimes. Flieber was a game changer for us. The interface is easy to use, with a bunch of critical information, and their algorithms that provide recommendations are top notch."

Tehsin Rashad

Operations Manager at Lifepro Fitness

"Finally a software that considers everything. Flieber considers all variables that no other software is able to pick up. It has helped us eliminate unnecessary stockouts that would hurt our Amazon business."

Wesley Wey

VP of Operations at Cabinet Health

"Flieber allows us to leverage technology to make demand planning and forecasting more streamlined and efficient. As a result, we have a less error prone process and have more time to spend making strategic decisions vs. data clean-up/analysis."

Hamza Khan

Project Manager at Wargames Delivered

"Flieber's people are simply amazing. They are making inventory management and forecasting more accurate and easier, allowing us to make data-based decisions quicker."

James Kelly

Co-Founder at Jagerita Holdings

"Flieber has replaced an extremely time intensive piece of our work with better results. It helps me predict my mid to long term demand and inventory replenishment needs. This is immensely important due to my long lead times and complex product portfolio due to multi-channel variation. It's great to have a tool that automates so much of this process."

Sara Maya

Supply Chain Manager at We The Brands

"Flieber efficiently consolidates data through integrations, simplifying decision-making and saving significant time. Its user-friendly interface ensures easy navigation, making it a valuable tool for streamlining operations and boosting productivity. Flieber is a game-change for supply chain planning in e-commerce companies."

Get started in 20 minutes

Forget complicated onboarding. Flieber has the flexibility to adjust to your specific operational flows. It comes with out-of-the-box integrations for every modern modern commerce tool you use and can be set up in as little as 20 minutes.

PS: Onboarding is free!

Your inbox just got smarter.

Sign up for Flieber emails and get the inside scoop on exclusive offers, newsletters, blog posts, and updates that'll keep you ahead of the game.

Thousands of ecommerce brands already trust Flieber- now it's your turn to crush stockouts and overstocks!

Let's start Fliebing!