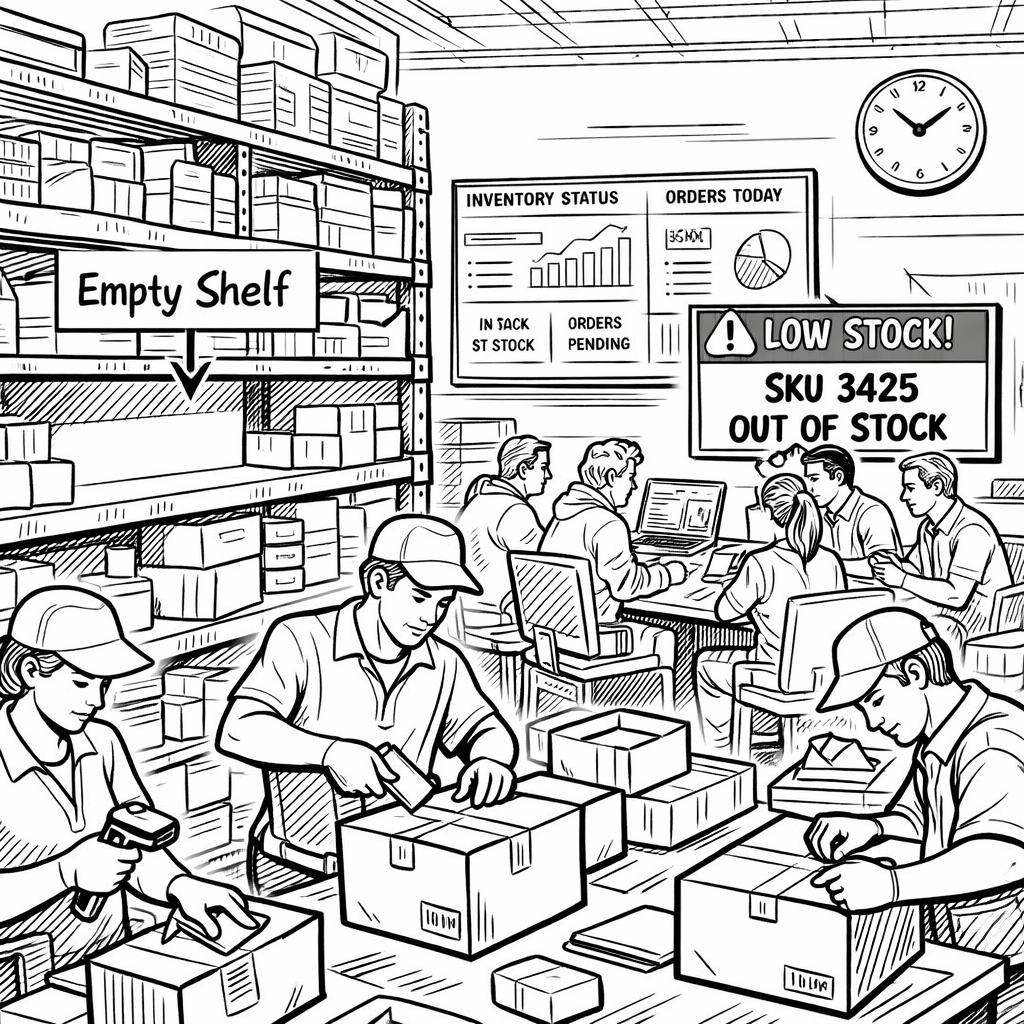

Have you ever sold a product you didn’t actually have in stock? If so, you’re not alone: 34% of businesses have been forced to delay shipping a product because they sold something they didn’t have in hand.

Though not uncommon, these types of mistakes aren’t great for your customers’ experience. So, how do you manage inventory replenishment processes efficiently enough to prevent it?

Inventory is the lifeblood of any product-based business. Without the right products, in the right place, at the right time, you can lose sales and customer trust.

This post will review seven common (and costly) inventory replenishment mistakes. We’ll also show you how to avoid those missteps, helping you nail your replenishment processes!

The Importance of Inventory Replenishment

You’ll need to have a baseline understanding of inventory replenishment before we can dig into the top mistakes to avoid. What is inventory replenishment? Inventory replenishment is the process of inventory forecasting, placing purchase orders, and receiving stock to your warehouse or fulfillment center. This process also may involve transporting stock between locations or warehouses to meet customer demand.

With reliable inventory replenishment processes in place, you’ll enjoy increased margins. You can save costs on storage fees, overstock, and deadstock while experiencing an increase in sales due to avoiding the dreaded stockout events.

When you don’t nail your inventory processes, you may face consequences like:

- Lost Sales: When your replenishment processes aren’t dialed, you’ll run into stockout resulting in lost sales.

- Wasted Inventory or Space: If you’re over-ordering safety stock to compensate for poor inventory replenishment systems, you’re paying for warehousing space you don’t need to hold onto inventory you’re not going to sell.

- Lost Trust: Stockouts, shipping delays, and canceled orders can cause you to lose the trust of your customers. This lost trust can spiral into consequences like negative online reviews and word of mouth.

- Platform Placement: If you have enough inventory challenges, you could fall out of favor with certain eCommerce platforms. As a result, your ranking on those platforms can suffer. Your product could even be delisted entirely!

- Time: You’ll lose valuable time fixing the issues caused by your inventory replenishment woes.

1. Lack of Effective Automation Software

The first inventory replenishment mistake you’ll want to avoid is failing to use effective automation software. What do we mean by this? In short, if you’re managing your inventory replenishment processes manually rather than leveraging automation, you are missing an opportunity and opening the door to potentially disastrous human error.

Manually managing replenishment is a mistake because humans tend to have a natural fear of understocking. As a result, studies show that you are likely to overstock when manually handling inventory replenishment.

Overstocking merchandise carries consequences like deadstock, high warehousing costs, and even stockout if you’re overstocking certain items and mistakenly understocking others.

Implementing a robust and effective automated inventory replenishment system is the best way to avoid making this mistake. You can use a system like Flieber to get a 360-degree view of sales, inventory, and supply chain data. These insights will help you make better decisions regarding replenishment.

2. Underutilizing Data

Another mistake you must avoid in your replenishment processes is the mistake of underutilizing data. Inventory management and planning are all about making decisions based on available data. If you cannot access the data you need, you will struggle to optimize your product catalog, analyze sales trends, explore market shifts, and more. In short: You won’t be able to build accurate forecasts.

When you underutilize data, you risk making decisions based on a partial picture of your market—or worse, making decisions based purely on gut instinct and guesswork. When you make your decisions this way, you may miss an upcoming trend, resulting in stockout and lost sales.

Related: Why Supply Chain Visibility Is The Secret To Staying Stockout-Free

On the flip side, you may overestimate the meaning of a past trend and overstock a product you aren’t able to move. You could also run into a situation where you run a promotion on a product that is out-of-stock or running low, resulting in a poor customer experience and wasted ad spend.

By classifying all your data, you can identify trends and categorize your products appropriately in ways that help you find—and accurately replenish—your best sellers.

The best way to avoid this mistake is to ensure you’re gathering all available data in a central location. This process ensures that you get the full picture of current inventory levels, sales trends, and more before you make replenishment decisions. Using software can automate your replenishment processes and help create actionable inventory forecasts.

3. Warehouse Management Challenges

We can’t discuss inventory without discussing the challenges associated with managing your warehouse. Without clear insight into your inventory, you may use your warehouse space inefficiently and pay for more warehouse space than you truly need.

The unnecessary additional space eats into your bottom line.

Additionally, without insight into your best-selling products, you may make the mistake of stocking all your products equally. This mistake results in overstock, leaving too much capital tied up in product that isn’t selling.

Related Read: 7 Best Inventory Planning Solutions to Help You Nail Replenishment

The best way to avoid making mistakes with your warehouse management is to use just-in-time inventory management processes. These practices will help you maximize the efficiency of your warehouse while minimizing your warehousing space and costs.

4. Overcomplicated Tech Stack

Mistake #4 that you may encounter regarding your inventory replenishment practices is utilizing an overcomplicated tech stack. When you use multiple tools that do not integrate or communicate with one another, you can run into numerous challenges.

A few issues that can arise when your tech stack is overcomplicated include:

- Data Inconsistencies: When different departments reference different systems for the same data point, someone may make a decision based on a wrong number. When there are too many tools with different data, it can be challenging to identify which system is the source of truth.

- Increased Manual Work: Manually combining data from multiple systems takes time, energy, and worker hours.

- Incomplete Data: You may also fall prey to the second mistake on this list—making decisions based on incomplete data from one system without seeing the full picture.

You can avoid this challenge by streamlining your tool stack to include only the tools you need. You’ll also want to ensure your tools integrate, allowing for transparency and open communication between systems. For example, Flieber integrates with Shopify, Amazon, NetSuite, and more. See a full list of our available integrations.

5. Focusing on the Wrong Metrics

Another mistake businesses make regarding their inventory processes is focusing on the wrong metrics. When you set KPIs based on vanity metrics or incomplete goals, you risk setting goals that won’t help improve your processes.

When you focus your energies on the wrong metrics, you’re wasting time and energy on efforts that will leave you running on a metaphorical hamster wheel instead of focusing on the metrics that will help you better serve your customers.

Avoid this challenge by focusing on metrics that truly matter. Some recommended KPIs you may want to consider include:

- Customer availability rate

- Stock life expectancy

- Sales Rate

- Days of Stock

6. No Real-Time Reporting

Can you report on your inventory data in real-time? To run your inventory replenishment processes efficiently, you need up-to-the-minute data you can use to make quick decisions and course-correct on the fly when needed.

When you don’t have real-time reporting capabilities, you make decisions based on old data. Consider a situation where you’re faced with a supply chain disruption. How can you mitigate the challenges associated with that disruption without access to real-time data to guide your decisions? Making decisions on irrelevant data is no more helpful than making decisions based on gut instinct.

Solve this problem by implementing a tool that offers real-time reporting and adjustments. Flieber lets you accelerate delivery or manage marketing and sales efforts on the fly to stretch inventory in a pinch. At the very least, don’t manage your inventory replenishment manually. If you need to wait for manual calculations, your data will always be out of date.

7. Leaning on Safety Stock

The last mistake you might make regarding your inventory replenishment is leaning too heavily on safety stock. Safety stock is important for every business. However, this stock is meant for emergencies—not to be used as a band-aid for poorly managed inventory processes.

When you rely too heavily on safety stock, you run into challenges like overstock, deadstock, and wasted warehouse space. Instead of optimizing your warehouse and ordering processes, your system can become bloated and inefficient, resulting in thousands of dollars of capital tied up in unnecessary inventory that isn’t selling.

You can avoid this challenge by implementing a robust inventory optimization tool and using just-in-time replenishment processes. These measures will help minimize your safety stock without putting you at risk of repeated stockout.

Managing Inventory Replenishment with Confidence

Effective inventory replenishment processes are vital to the success of your business. To avoid lost sales from stockout, overspending on warehouse space, and more, you need to ensure you have the tools and practices to keep your inventory replenishment processes humming.

Avoiding the mistakes listed in this post is a great way to start crushing your inventory processes, but to truly manage your inventory and help your business reach its maximum potential, you need to implement an inventory planning tool.

Flieber’s inventory planning tool uses machine learning and data analytics to streamline your supply chain and inventory management processes, helping you make the right decisions regarding inventory replenishment. To see how Flieber can help your business, schedule a demo today!

.jpg)