Reorder point in ecommerce operations is the inventory level at which a replenishment order should be triggered. It ensures remaining stock covers expected demand during lead time, reducing the risk of stockouts.

1. What it is (Definition)

A reorder point is the inventory level at which a replenishment order should be triggered to avoid running out of stock. In ecommerce operations, it defines the moment when inventory transitions from “sufficient” to “action required.”

The reorder point is not about how much to order, but about when to order. It acts as a signal that remaining inventory must cover expected demand during the supplier lead time, plus any buffer needed to absorb uncertainty.

Operationally, the reorder point protects continuity. If replenishment is triggered too late, inventory reaches zero before new stock arrives. If it is triggered too early, excess inventory accumulates and ties up cash.

For ecommerce brands, the reorder point is one of the most important control mechanisms linking demand, lead times, and inventory risk.

2. Who it’s for

Reorder points are especially important for mid-market ecommerce brands and aggregators operating between $5M and $100M in annual revenue. At this scale, inventory volume and lead times are large enough that timing mistakes become expensive.

Shopify-based ecommerce businesses rely on reorder points to manage fast-moving SKUs without constant manual monitoring. As order volume increases, intuitive reordering becomes unreliable.

Amazon and Walmart third-party sellers depend heavily on reorder points to avoid stockouts that damage marketplace performance. Long inbound lead times and strict availability expectations make precise timing critical.

Multichannel ecommerce teams managing shared inventory pools use reorder points to trigger replenishment based on total demand rather than channel-specific signals. Without this, inventory is often reordered too late or too aggressively.

Reorder points become essential once inventory replenishment can no longer be handled reactively or visually.

3. How it works

The reorder point is determined by expected demand during lead time and any additional buffer required for uncertainty. Conceptually, it represents the amount of inventory that should remain on hand when a new order is placed.

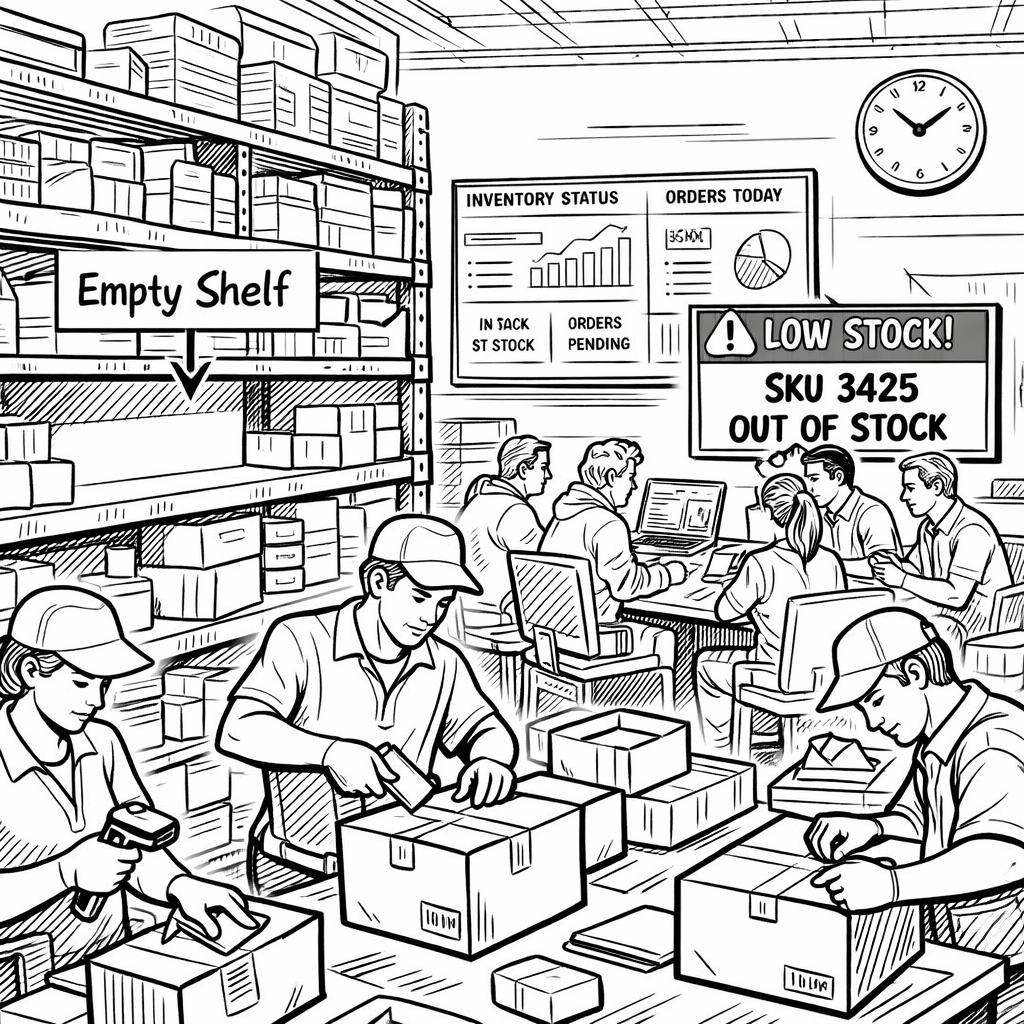

As sales occur, inventory declines. When inventory reaches the reorder point, a purchase order or replenishment action is triggered. Ideally, the inbound inventory arrives just as on-hand stock approaches depletion, avoiding both stockouts and excess.

The accuracy of a reorder point depends on two inputs. First, the demand rate used should reflect expected near-term sales. Second, the lead time assumption should reflect how long replenishment actually takes, not just contractual timelines.

In ecommerce operations, reorder points are often dynamic rather than static. As demand patterns change due to seasonality, promotions, or growth, reorder points must be adjusted. Static reorder points quickly become outdated in volatile environments.

Reorder points are most effective when paired with continuous monitoring and exception handling. Unexpected demand spikes or delayed shipments may still require intervention, even when reorder logic is in place.

4. Key metrics

Inventory turnover is influenced by how reorder points are set. Reorder points that trigger too early increase average inventory and depress turnover. Reorder points that trigger too late may temporarily inflate turnover while increasing stockout risk.

Sell-through rate provides context for reorder effectiveness. Poor sell-through combined with frequent reorders suggests reorder points are too aggressive relative to true demand.

Weeks of supply is closely tied to reorder points. A reorder point effectively defines the minimum weeks of supply the business is willing to operate with, based on lead time and buffer assumptions.

Fill rate reflects the service outcome of reorder point accuracy. Well-calibrated reorder points help maintain stable fill rates by ensuring replenishment occurs before inventory is exhausted.

Together, these metrics help teams evaluate whether reorder timing is aligned with demand, lead times, and service expectations.

5. FAQ

Is reorder point the same as reorder quantity?

No. Reorder point determines when to reorder. Reorder quantity determines how much to order.

Do all SKUs need a reorder point?

Most replenished SKUs do, but products with one-time buys or end-of-life items may not.

Can reorder points be static?

They can be, but static reorder points often fail in ecommerce environments with changing demand.

How does safety stock relate to reorder point?

Safety stock is typically included in the reorder point as additional buffer above expected lead-time demand.

What happens if reorder points are set incorrectly?

If set too high, inventory accumulates unnecessarily. If set too low, stockouts become frequent.